You’ve just received a call from your bindery service provider informing you that they have stopped drilling your project because text or graphics are being drilled through. Now what?

If you’re lucky, the content or design being drilled through is inconsequential. But what if the data being compromised is pricing information, or, product identification codes? Perhaps it’s a data chart? You could be facing a reprint or a significant discount to your customer, who will most likely be unhappy with the final product.

Allowing for drill hole margins is crucial to meeting the quality expectation of your customer. In all likelihood, they expect the printer to think of attributes like this. Failure to include necessary margins to avoid drilling text or graphics will result in cosmetic failures, at best, or the elimination of critical information, at worst.

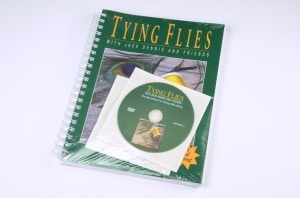

Whether a book is being drilled for inclusion into a standard three ring binder or a special five hole automotive post binder, an appropriate gutter margin must be allowed on both text and covers. Also, it’s important not to forget how drilling may effect any fold out forms or bound reply cards. Each of these items may be easily overlooked, particularly if your company does not consistently produce drilled products.

Involving the Sales and Planning Professionals at Allied Bindery can help you avoid these types of problems. We can provide you with the appropriate margins or templates that allow you to effectively plan for projects with drilling requirements. Give us a call at 248-588-5990 and let us help you achieve your customer’s expectations.