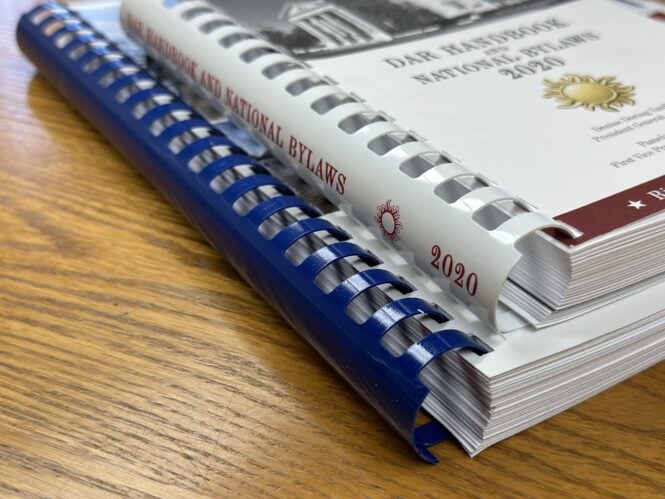

Plastic comb binding is a popular method of bookbinding. It involves using a plastic comb-like spine to secure the pages of a document together. We often use this process with customers that need reports, presentations, manuals, and other documents that will lie flat when opened.

Typically, Allied Bindery comb binding process involves the following steps:

- Hole punching: We punch the pages of the document with evenly spaced rectangular holes along one edge. We do this with a specialized comb binding machine or a standalone hole punch designed for comb binding.

- Comb insertion: We open the plastic comb spine, which consists of a series of plastic rings attached to a spine, by spreading the rings apart. Then, we insert the comb into the punched holes, with the rings fitting through the holes and the spine resting against the back edge of the document.

- Closing the comb: Once the comb is inserted, we close the rings by pressing them back together, securing the pages in place. Our comb binding machine has built-in mechanisms for closing the comb.

Lastly, our plastic comb binding offers several advantages. It allows for easy addition or removal of pages, making it convenient for documents that may need frequent updates. The plastic combs come in various sizes, accommodating different document thicknesses.

The other mechanical binding services at Allied Bindery are:

You can read more about plastic comb binding by visiting the GBC website.