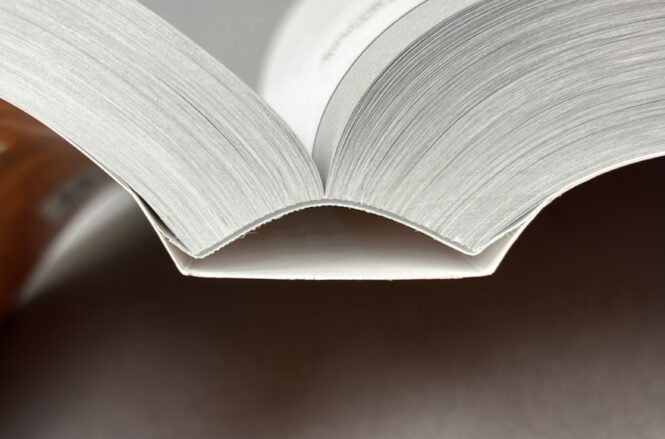

Layflat binding, also sometimes known as Otabind, is a type of binding that enables a book to lay flat when opened.

In the Allied Bindery layflat binding process, we collate the pages of a book together, roughen the edge that will be glued, and apply an adhesive to the roughened edge. Then, we apply a strip of cloth, known as gauzing, to the spine of the book, covering the roughened edge and providing reinforcement.

During the gauzing process, we cut the cloth to the appropriate size and apply it to the spine, with the edges of the gauze extending slightly onto the inside of the cover of the book. We glue the strip of cloth to the text and then to the cover, such that the cover and spine do not get glued together.

We apply the gauzing in layflat binding to help the book lay flat without compromising its structural integrity. The gauze is typically made out of cotton, linen, or synthetic fibers and is designed to be flexible and tear-resistant.

At Allied Bindery, we use layflat binding for our customers’ softcover books, such as novels, textbooks, and trade paperbacks. We do not use it for hardcover books, which require more complex binding methods to attach the cover to the pages.

As a generic term, layflat binding also applies to any binding technique that allows a book to lay flat when opened to any page, without the need to hold the pages down or use a book weight. We offer the following layflat binding services:

- Plastic Coil Binding: With plastic coil binding, we insert a plastic coil or spiral through small holes punched along the edge of a stack of pages. Plastic coil is also a durable binding option that can withstand repeated use and handling, making it ideal for frequently referenced materials. Read more about Allied Bindery’s services here …

- Twin-Loop Wire Binding: Twin-loop wire binding, also known as Wire-O binding or double-loop binding, is a bookbinding method that involves threading a double-looped wire through a series of closely spaced holes punched along the edge of a stack of pages. The wire is then crimped at both ends to keep the pages securely bound together. Read more about Allied Bindery’s services here …

Read more about the history of bookbinding and all binding techniques here.